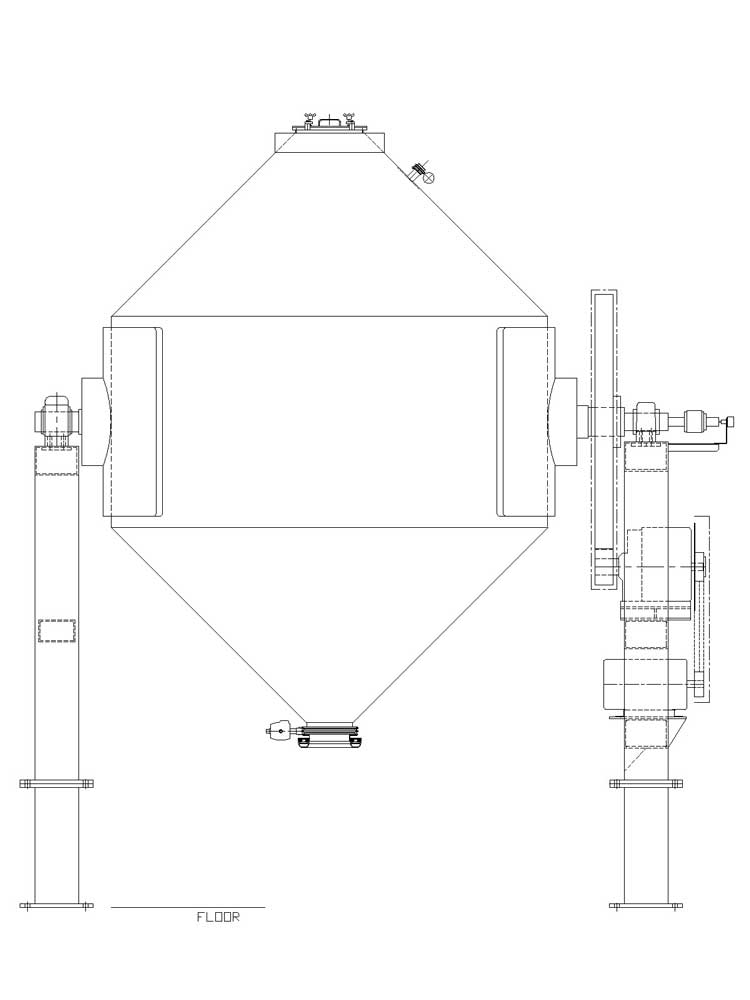

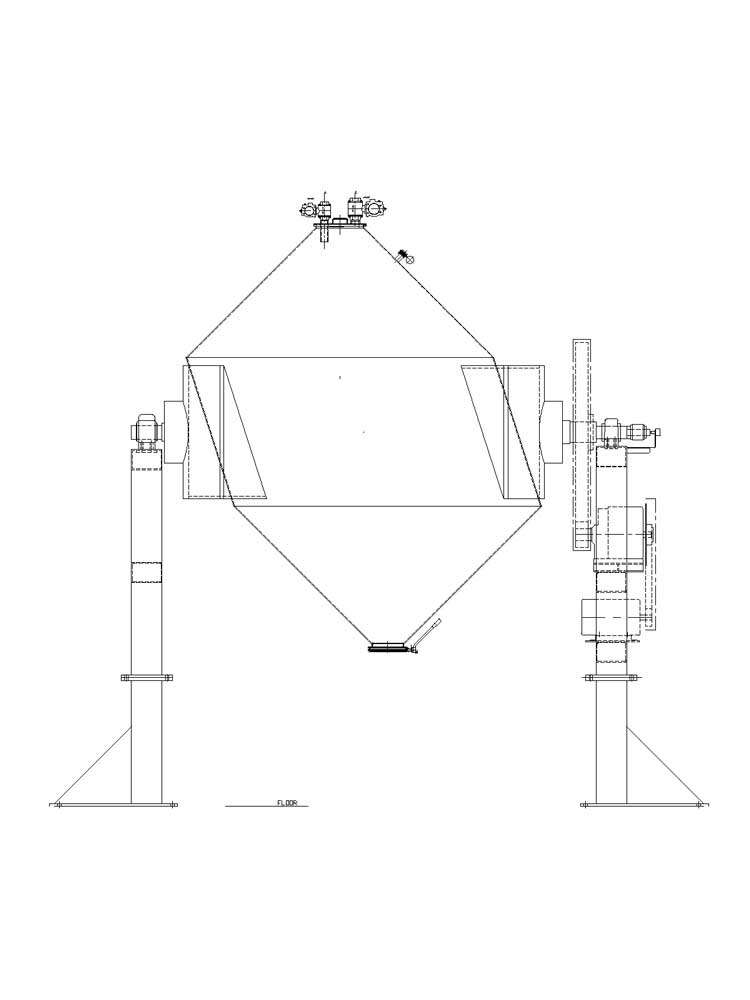

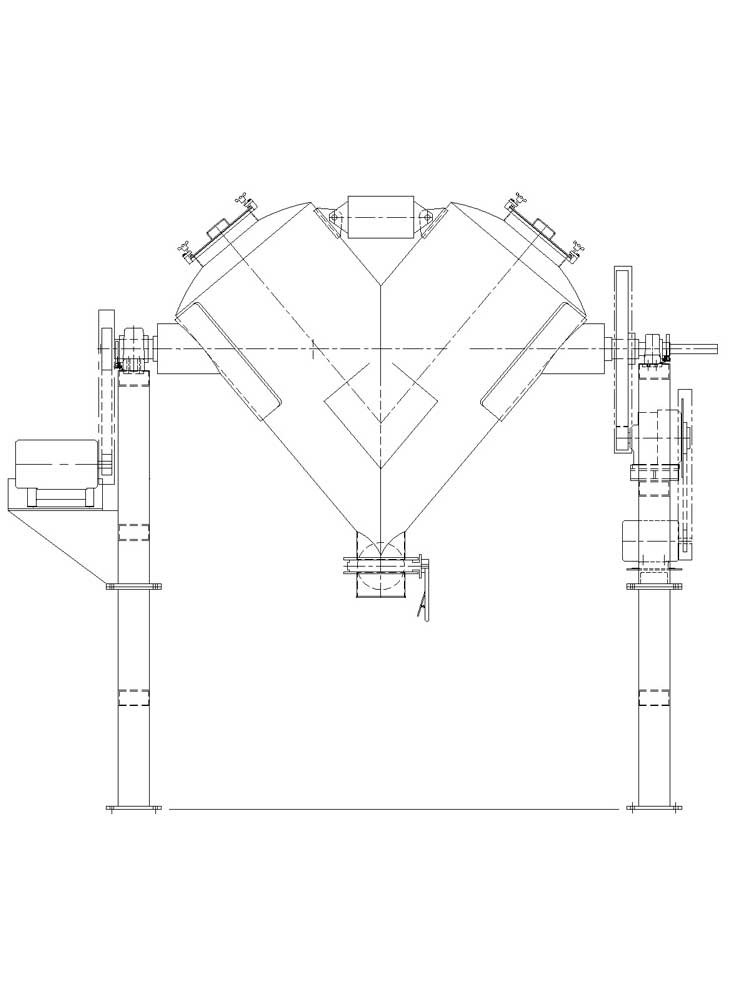

Blending Equipment for Ceramic Powders

The global authority of tumble mixing and drying, GEMCO’s 100+ years of engineering and manufacturing expertise ensure our Ceramics clients achieve their optimized blend results time and time again.

GEMCO drying and blending equipment for ceramic powders are used to attain the most efficient, uniform/homogeneous, repeatable blending results available in the world. Regardless of mixture weight, size, or shape, GEMCO tumble mix and dry solutions mix and blend to perfect uniformity in less time, with less power and waste, and guarantee the lowest mix standard deviation available anywhere.

Ceramic Powder Blender Options

Our Ceramic Powder Mixing and Drying equipment systems include:

- Test Lab to large scale 400ft3 production

- Tough, proven design guaranteeing outstanding safety, service life, and reliability, lowering maintenance costs

- Vacuum drying allows processes to proceed faster at lower temperatures

- Lot sizes ranging from 10kg to 1800kg with full traceability of the different batches blended

- 316 stainless steel contact parts with pharmaceutical-grade (F.D.A.) finishes, preventing lot-to-lot contamination

- Technology Test Center facility to help define your optimized mix and scale

- Decades of expertise optimizing mixing and drying within the Ceramic industry